Grikštaitė J. (2008) Business process modelling and simulation: advantages and disadvantages. Global Academic Society Journal: Social Science Insight, Vol. 1, No. 3, pp. 4-14. ISSN 2029-0365. [www.ScholarArticles.net]

Author:

Jūratė Grikštaitė, Vilnius Gediminas Technical University, Lithuania

Abstract

In the context of increasingly changing business environment, organizations need reliable tool for assessing and forecasting business processes. Such tool might be timely and manageable modelling and simulation (M&S) of business processes. M&S allow visualisation, imitation of behaviour and forecasting of wide scope of business processes. Scholars describe many positive and negative aspects of applying modelling and simulation of business processes within the organisation. Thus, the aim of the article is to contrast main advantages and disadvantages of business process modelling and simulation, and to assess usage of M&S in planning of business processes. The article overviews and sums-up opinions of Chang and Makatsoris (2001), Johnson (2000), Brown et al. (2000), Gould (2000), Giaglis et al. (2004), Banks (2000), Greasley (2004) and other researchers; and supports the findings with practical examples on how implementation of M&S has helped to improve business processing of huge transnational corporations.

Introduction

Increasing competition, growing customer requirements, shift of technologies and other rapid market changes push businesses into higher risk and may invoke serious consequences for them. Therefore organizations should look for ways how to diminish business risk. Barjis (2008) maintains that “the recursive activities of adapt-change-improve would be a driving force for the 21st century enterprises”; therefore business process modelling and simulation might be a crucial tool for assessing business processes.According to Perumpalath (2005), an organisation may be considered as a complex system comprised of functions, processes, resources, customers, suppliers etc. Business process change involves changes in people, processes and technology (Indihar-Stemberger et al., 2003). A manageable model of reality is necessary in order to understand organization‟s components and their interrelationships (Perumpalath, 2005). Barjis (2008) also stresses importance of business process modelling and simulation, and proposes that it opens promising research field “as the potential and full capacity of enterprise modelling and simulation still have yet to be revealed”. Despite bunch of evident advantages, some authors describe difficulties related to implementation of modelling and simulation in practice. These are related to heavy time and money consumption as well as with reliability of models. Thus, the aim of the article is to contrast main advantages and disadvantages of business process modelling and simulation, and to assess usage of M&S in planning of business processes.

Essence of business process modelling and simulation (M&S)

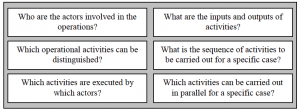

Magretta (2002) defines business modelling as a managerial equivalent of the scientific method: hypothesis which is tested in action and raised when necessary. According to Gordijn et al. (2000), the main goal of a business model is to answer the question: “who offers what to whom and what expects in return”. Therefore, these authors emphasise concept of value, which, they propose, should be the central notion in any business model “explaining the creation and addition of value in a multi-party stakeholder network, as well as the exchange of value between stakeholders”. The researchers agree that a business model does not state how value-creating activities are carried out. Meanwhile business process modelling ensures creation of a common approach for work to be carried out; incremental improvement of processes (e.g. efficiency); support of processes by workflow management systems; as well as analysis of properties of a process (Gordijn et al., 2000). To present the how, a business process model typically shows the design decisions displayed in Figure 1. Referring to Patel and Hlupic (2000), business process modelling is a technique used to analyse and model business processes. Sparks (2000) proposes that business process modelling allows fixing main principles and procedures, describing how business is organized. Besides, modelling enables customer to visualize processes. It helps understanding operational links and impact of interactions. It is evident that business process model should be a flexible, customized and accessible tool (Bahrami et al., 1998). This tool, according to Sparks (2000), involves the following elements: primary (input) data, defined results, used resources, tasks which are fulfilled in certain order as well as factors influencing the process.

Figure 1. Design decisions of business process model (according to Gordijn et al., 2000)

Figure 1. Design decisions of business process model (according to Gordijn et al., 2000)

Business process model is devoted to specification of causal and conditional links between business operations, Barjis and Ilkov (2004) propose. These authors maintain that causal link is a link between two business operations when one operation causes beginning of another operation, while conditional link is a link where the end of one operation determines start or end of another operation. Both, causal and conditional links are optional, i.e., start of a new business operation depends on certain conditions. Indihar-Stemberger et al. (2003) highlight that many different methods and techniques can be used for modelling business processes in order to give an understanding of possible scenarios for improvement. The simulation modelling shows the process as a whole, drawbacks of the existing process, bottlenecks in the process execution and provides critical insight into process execution. The conditions for the introduction of simulation modelling into process modelling can be summarized as follows (Pidd cited by Indihar-Stemberger et al., 2003 and by Greasley, 2004):

- Dynamic – process behaviour varies over time.

- Interactive – process consists of a number of components which interact with each other.

- Complicated – process consists of many interacting and dynamic objects.

As most organizational systems have these characteristics and thus simulation would seem to be an ideal tool for providing information on the behaviour of an organization (Greasley, 2004). In Banks’ (2000) opinion, simulation is an indispensable problem-solving methodology for the solution of many real-world problems. According to this author, simulation is used to describe and analyse the behaviour of a system, ask “what-if” questions about the real system, and aid in the design of real systems. Banks (2000) maintains that both existing and conceptual systems can be modelled with simulation. Barjis (2008) emphasize that business process modelling and simulation play a significant role in studying, analyzing, optimizing, comparing different scenarios, and measuring the effects in advance. This researcher agrees that simulation is a safe and inexpensive way of studying the impact of changes and revealing hidden behaviours of a complex system. Business process simulation means execution of model. Simulation may be defined as a collection of methods and applications to imitate the behaviour of real systems (Aguilar-Savén, 2004). According to Smith (2000), simulation is the process of designing a model of a real or imagined system and conducting experiments with that model. The purpose of simulation experiments is to understand the behaviour of the system or evaluate strategies for the operation of the system (Smith, 2000). Iansiti (1998) highlights that modelling and simulation (M&S) do not act isolated: technological and non-technological factors are closely integrated and act in common. Modelling alone may not reveal sufficient information about the processes (Barjis, 2008). M&S may be considered as endeavour to imitate real processes and infrastructure (Stanford and Snead, 2000). Most of simulation tools are designed as interactive tools to be used by a human planner not as real time decision-making tools, which are directly linked to control system to dispatch tasks. Simulation tools aid human planner to make a right decision by providing information. However, human planner should be able to interpret and modify the plan in order to achieve most precise results (Chang and Makatsoris, 2001). Analysing M&S, it is important to take into account adequacy and resolution which are main features of M&S. Adequacy may be considered as precision of model in comparison with real world. Model or simulation is adequate if it exactly corresponds or reflects object or experience. Resolution is used for representing aspects of real world in a model or simulation; it may be described as degree of particularity and accuracy (Stanford and Snead, 2000). Johnson (2000) highlights that resolution and adequacy is not the same: an adequate model does not necessarily have high resolution and vice versa. The choice of these features depends on aims of M&S. Usually the major aim of M&S is to provide quick response for decision-makers of the organization and a common picture of organization for specialists of know-how creation. Business simulation is a flexible tool that may be used in various fields of businesses (e.g. financial planning, risk management, forecasting and business process modelling) both at operational and strategic levels. Business simulation involves competitive strategy, management of product portfolio, services and after-purchase services, human resources planning, pricing, financial forecasting as well as investment planning (Hauke and Berendes, 2001). Simulation is the imitation of the operation of a real-world process or system over time. According to Banks (2000), it may be adapted to short-term and long-term scenarios, such as analysis of long-term situations (e.g. market simulation) or concrete cases (e.g. one-time investment modelling). This author proposes, that simulation involves “the generation of an artificial history of the system, and the observation of that artificial history to draw inferences concerning the operating characteristics of the real system that is represented”. For instance, Wedgwood global distribution centre used M&S to verify whether their new automated storage and retrieval system would work properly in conjunction with the existing material handling system and to diagnose causes of the possible problems. M&S helped Wedgwood to verify a range of ideas – including changing process routes, extending conveyors, and changing control logic – to rectify the design issues (Paragon Simulation, 2008d). M&S are widely used for optimization of business processes. It is the tool helping managers to make rational decisions and thus to protect organization from failures and save the costs. For instance, M&S of operation of TESCO distribution centre showed that two fewer automatically guided vehicles (AGVs) were needed than indicated by the original spreadsheet calculations – a total saving of £160,000 (Paragon Simulation, 2008a). As mentioned above, modelling enables customer to visualize processes because simulation gives breath to them. Dynamic simulation helps customer to analyse “what-if” scenarios, to estimate costs and to forecast the activity. Animation of processes facilitates forecasting distribution of responsible staff, e. g. top managers and other employees. In general, M&S technology is usage of models by storing data as database for managerial and technical decisionmaking.

Advantages and disadvantages of business process M&S

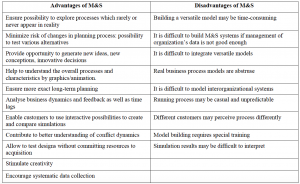

There are various tools that facilitate gaining clearer picture of nowadays business activities: spreadsheets, tables, graphs and state reports. But all these tools do not allow fully perceiving factors that condition future profitability. As Hauke and Berendes (2001) describe, business analysts and linear managers require a flexible instrument, which enables them to build a model and to assess possible future scenarios at the same time analysing multi-related actions and their plausible influence on a process. According to Hauke and Berendes (2001), M&S support and supplement electronic spreadsheets, On-Line Analytical Processing (OLAP) tools and risk analysis software, which enables linking both historical data and “cause-sequence” assumptions related with future activity. Xerox Corporation used M&S seeking to optimize use of automatically guided vehicles (AGVs) of its large assembly area, which helped to save about £180,000. The model cost around 13-days to build and deliver (Paragon Simulation, 2008b). Indihar-Stemberger et al. (2003) highlight that the main advantage of simulation modelling is in its‟ integration of following functions: analysis and assessment of business processes, either in quantitative or qualitative terms; development of ”to-be” models in order to examine “what-if” scenarios and export to implementation platforms, such as workflow management and enterprise resource planning systems. Hauke and Berendes (2001) maintain that business analysts intuitively create and define a business model in graphical way and together with linear managers analyse “what-if” cases and consider “how to reach?”. This way, business simulation may facilitate decision-making by forecasting sophisticate „what-if‟ scenarios, providing reliable way to evaluate similar effects of different decisions and variables, propose Hauke and Berendes (2001). Bahrami et al. (1998) highlight that M&S may be used for optimization of business processes. Modelling and simulation help to make better decisions, e.g. to distribute work operations with regard to available resources, to decide about work-schedule or application of certain business rules. For instance, in order to increase capacity, efficiency and airline-passenger service, BAA company that owns and runs 7 UK airports, commissioned Heathrow Terminal 5. BAA‟s process designers and analysts used the model to compare various scenarios until they were confident that their design offered the best compromises and met key targets efficiently without wasteful redundancy. The results of the modelling greatly influenced the size and layout, and service point numbers and positioning of Terminal 5. Besides, BAA used the results in negotiations to convince airlines that “customer experience” expectations would be met without acceding to demands for unnecessary extra capacity (Paragon Simulation, 2008c). Results of modelling process and experiments may be useful to analysts, customers and managers. By tracing development of organizational processes, knowledge acquired from M&S may be helpful to manage future changes. Thus, M&S help organization to make crucial decisions. This is performed by making a query or search function for a certain process and by generating various reports that are accessible to all members of the organization (Hauke and Berendes, 2001). Eventually, as Hauke and Berendes (2001) describe it, benefit of simulation is improvement of two main fields: decision-making and communication. Simulation enables evaluation of real influence of financial or non-financial decisions on future activity. Despite of accessibility of M&S, organizations usually meet practical problems while trying to model detailed activity or realize changes in nowadays environment, Giaglis et al. (2004) note. These authors propose that problems of modelling and simulation arise due to such reasons as interactions between separate tasks and informal nature of tasks that burden their analysis and documentation. As Smith (2000) note, real systems are extremely complex and a determination must be made about the details that will be captured in the model. Some details must be omitted and their effects lost or aggregated into other variables that are included in the model. In both cases, an inaccuracy has been introduced and the ramifications of this must be evaluated and accepted by the model developers. Another limitation, Smith (2000) proposes, is the availability of data for describing the behaviour of the system. It is common for a model to require input data that is scarce or unavailable. This issue must be addressed prior to the design of the model to minimize its impact once the model is completed. Although simulation can be applied in the organization, a model developed for a nontrivial problem will consume a significant amount of resource in terms of staff time. Both time and cost elements need to be considered (Greasley, 2004). Meanwhile, Brown et al. (2000) proposes that the crucial barrier to perceive M&S is lack of knowledge. The most of the employees do not perceive benefit of M&S or do not know how to determine needs and to use proper tools useful to the certain project. Unfortunately, such passivity is also strengthening by the organization which neither approves, nor stimulates project managers to take a risk. Sometimes project managers cannot ensure if investment in M&S prove out. If project management wants to invest in technologies, it will face critics if results of investment are not positive. Thus, project managers should evaluate risk of costs. Some of the project managers prefer traditional views: they create expensive models, use work-, time- and money-consuming experiences. This leads to overspending of resources. According to Brown et al. (2000), “high-technology based project will not be successful if the M&S are not involved in development of the project”. Despite of this, the most of investment decisions are based on intuition or needs. Usually decisions are made without detailed quantitative analysis. Although organizations invest in M&S, they usually lack of cost-benefit analysis, Brown et al. (2000) note. Besides, due to the lack of structural business case analysis, it is difficult and sometimes impossible to create or validate investment strategy.

Table 1. Main advantages and disadvantages of M&S (Chang and Makatsoris, 2001; Johnson, 2000; Brown et al., 2000; Gould, 2000; Giaglis et al., 2004; Banks, 2000; Greasley, 2004)

Table 1. Main advantages and disadvantages of M&S (Chang and Makatsoris, 2001; Johnson, 2000; Brown et al., 2000; Gould, 2000; Giaglis et al., 2004; Banks, 2000; Greasley, 2004)

Apart from the above discussed advantages and disadvantages of M&S, the following items were revealed after summarizing opinions of Chang and Makatsoris (2001), Johnson (2000), Brown et al. (2000), Gould (2000), Giaglis et al. (2004), Banks (2000) (see Table 1). Companies should use M&S more widely, taking into consideration that M&S possess such advantages as: diminishing costs of situation evaluation, perception of business as system, diminishing probability of wrong decisions, etc. In addition, it is much easier to accept reliable simulation results, which have been modelled, tested, validated, and visually represented, instead of one person‟s opinion on the results that will occur from a proposed design (Banks, 2000). But on the other hand, usage of M&S have such disadvantages as financial and time costs of model creation and problems arising from the fact that it is difficult to reflect and forecast detailed real situation and especially external factors affecting the organization.

Conclusions

- Business process M&S usually do not act separately. They supplement each other. Static, dynamic, interactive or complicated business process modelling describes how business is organized and simulation imitates the behaviour of real systems.

- Business process M&S possesses both, advantages and disadvantages. On one hand, M&S help organization to manage changes more effectively, enable saving time and costs by analysing business changes, facilitate creation and implementation of business strategy, allow better perception of business process as the whole, create organization‟s informational base. In short, M&S facilitate further decision making. On the other hand, while applying business process, M&S organizations may meet some problems caused by complexity of real business processes, informal nature of tasks, and customers‟ different perception of the process. Additional problems may arise in M&S of interorganizational activities.

References

- Aguilar-Savén R. S. (2004) Business process modelling: Reviewand framework. International Journal of Production Economics, No. 90, pp. 129–149.

- Bahrami A., Sadowski D., Bahrami S. (1998) Enterprise Architecture for Business Process Simulation. Proceedings of the 1998 Winter Simulation Conference. Available at http://www.informs-cs.org/wsc98papers/192.pdf.

- Banks J. (2000) Introduction to simulation. Proceedings of the 2000 Winter Simulation Conference. Available at: http://www.informs-cs.org/wsc00papers/003.pdf.

- Barjis J. (2008) Enterprise, Organization, Modeling, Simulation: Putting Pieces Together. Proceedings of EOMAS 2008. Available at: http://ftp.informatik.rwth-aachen.de/Publications/CEUR-WS/Vol-338/paper1.pdf.

- Barjis J., Ilkov I. G. (2004) Integrating Business Process Modeling and Simulation. The Society for Modeling and Simulation International. Available at: http://www.scs.org/scsarchive/getDoc.cfm?id=1112.

- Brown C. D., Grant G., Kotchman D., Reyenga R., Szanto T. (2000) Building a Business Case for Modeling and Simulation – defense contracts. Acquisition Review Quarterly, Fall. Available at: http://www.findarticles.com/p/articles/mi_m0JZX/is_4_7/ai_78177429.

- Chang Y., Makatsoris H. (2001) Supply chain modeling using simulation. International Journal of Simulation, Vol. 2, No. 1, pp. 24-30. ISSN 1473-8031.

- Giaglis G. M., Paul R. J., Doukidis G. I. (2004) Simulation For Intra- And Inter-Organisational Business Process Modelling. Assess-IT. Available at: http://www.brunel.ac.uk/research/assessit/8.pdf.

- Gordijn J., Akkermans H., van Vliet H. (2000) Business Modelling is not Process Modelling. Conceptual Modeling for E-Business and the Web, Vol. 1921/2000, pp. 40-51, ISBN 978-3-540-41073-7.

- Gould L. S. (2000) Engineering a Better Business – Enterprise Modelling. Automotive Manufacturing & Production, September, 2000. Available at: http://www.findarticles.com/p/articles/mi_m0FWH/is_9_112/ai_65773553.

- Greasley A. (2004) Simulation Modelling for Business. Ashgate Publishing, p. 226.

- Hauke U., Berendes K. (2001) Powersim‟s Business Modeling and Simulation Tools are Built Right in to SAP SEM. SAP Insider, October-December. Available at: http://www.powersim.com/common/pdf/sap-powersim.pdf.

- Iansiti M. (1998) Technology Integration: making critical choices in a dynamic world. Harvard Business School Press, p. 256.

- Indihar-Stemberger M., Popovic A., Bosilj-Vuksic V. (2003) Simulation and information systems modelling: a framework for business process change. Proceedings 15th European Simulation Symposium. Available at: http://www.scs-europe.net/services/ess2003/PDF/BUS06.pdf.

- Johnson J. L. (2000) Challenges for modeling and simulation. Office of the Secretary of Defence: Program Analysis and Evaluation. Available at: https://www.dmso.mil/public/library/efms/2000/wed524/qdr/01.pdf.

- Magretta J. (2002) Why business models matters? Harvard Business Review, R0205F, pp. 3-8.

- Paragon Simulation (2008a) Case Study: Tesco – Capacity planning for distribution centre. Available at: http://www.paragonsimulation.com/live/casestudy/15a.pdf.

- Paragon Simulation (2008b) Case Study: Xerox Electronic Assembly. Available at: http://www.paragonsimulation.com/live/casestudy/17a.pdf.

- Paragon Simulation (2008c) Case Study: BAA – Heathrow Terminal 5 planning. Available at: http://www.paragonsimulation.com/live/casestudy/5a.pdf.

- Paragon Simulation (2008d) Case Study: Wedgwood – Global Distribution Centre. Available at: http://www.paragonsimulation.com/live/casestudy/16a.pdf.

- Patel N., Hlupic V. (2000) Dynamic business process modelling (BPM) for business process change. International Journal of Simulation, Vol. 2, No. 2, pp. 51-64. ISSN 1473-8031.

- Perumpalath B. P. (2005) Modelling Business Process: An Integrated Approach. Available at http://dissertations.port.ac.uk/30/01/MBA_Dissertation.pdf.

- Smith R. (2000) Simulation: The Engine behind the Virtual World. Simulation 2000, Vol. 1. Available at: http://www.modelbenders.com/papers/sim2000/SimulationEngine.pdf.

- Sparks G. (2000) The Business Process Model. Available at: http://www.sparxsystems.com.au/ WhitePapers/The_Business_Process_Model.pdf.

- Stanford T., Snead Ch. (2000) Introduction to Modeling and Simulation. Defence Modeling and Simulation Office. Available at: https://www.dmso.mil/public/library/efms/2000/mon522/ms101/ms101_ shortversion.pdf.